September 19, 2025, ©. Leeham News: We do a series about ideas on how the long development times for large airliners can be shortened. New project talks about cutting development time and reaching certification and production faster than previous projects..

The series will discuss the typical development cycles for an FAA Part 25 aircraft, called a transport category aircraft, and what different ideas there are to reduce the development times.

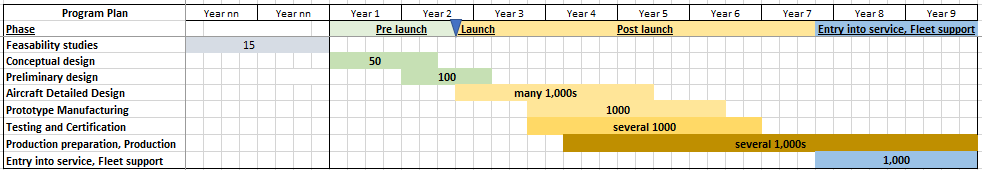

We will use the Gantt plan in Figure 1 as a base for our discussions.

*** Special thanks to Ron Everlove for helping with this article***

Conceptual System Design

During the Conceptual design phase, the team needs to mature the design of the entire aircraft, including structures, systems, interior, etc. For a 14 CFR Part 25 airliner, the design needs to comply with various systems requirements, such as Part 25.1309, for equipment, systems, and installation. The work to comply with such regulations begins at the Conceptual design phase.

The system team needs to identify several aircraft functions. Examples of requirements:

- provide required thrust during all phases of operation

- provide required directional control during all phases of operation

These may sound obvious, but they are essential for subsequent analyses and compliance determinations. The team needs to evaluate failure cases for each of these functions and determine their effects.

The “provide thrust” function needs to be broken down into various phases, such as taxi, takeoff, climb, cruise, etc. The team will need to look at failure cases such as uncommanded thrust increase, asymmetric thrust, one-engine-inoperable, etc. Some cases may cause a slight increase in workload for the pilots. Other cases may result in injuries or death. The team would assign hazard levels based on the effects of the failure cases.

Similarly, if the team examines the “provide directional control” function, it needs to evaluate the impact for each phase. We are skipping flight phases for now and focusing on taxi, takeoff, and landing. These phases may require more granularity for this analysis. If a plane loses directional control at a very low speed, it may not be a big problem. If the plane loses directional control at landing and veers off a runway, it could result in a fatal crash.

System Level Requirements

Armed with the functions, failure cases, and hazard levels, the systems team can start evaluating system-level functions and requirements to develop the architectures.

For the uncommanded thrust increase case, would a fan speed and throttle quadrant position synchronization be sufficient?

For the ground directional control, is a backup system needed for the nosewheel steering, or can we improve the reliability of certain nosewheel steering components to meet the failure probabilities needed?

Again, aircraft design is an iterative process, and the back-and-forth communication within a cross-functional team is absolutely key for getting to the design maturity needed at this phase and thus securing the project’s plans (now or for later development stages. Having to redo the previous stage analysis later to change a system architecture is very detrimental to the project).

Supplier Interaction

Depending on make/buy decisions for system parts, the team would also start collaborating with suppliers. Suppliers would present their solutions and provide recommendations. They could pitch off-the-shelf, modified, brand-new, or a combination of system ideas.

This is where supply chain, engineering, manufacturing, customer support, and program management need to review these proposals together to identify the best solution for the program. Performance, cost, schedule, and risk are the topics at this stage.

By the end of the Conceptual system design phase, the systems team should have a good understanding of all key systems and be able to agree on system architectures. These would then be subject to more detailed analyses in later program phases.

AI Support for Conceptual System design?

Can AI help speed up the process? We decided to put ChatGPT to the test again. This is the prompt we entered:

I’m designing a Boeing 737 and Airbus A320 replacement aircraft. It’ll use a hybrid propulsion system. Would you generate a list of aircraft functions for the safety analysis?

The following is the output:

Absolutely—here’s a comprehensive, system-oriented master list of aircraft functions you can use as a starting point for your Functional Hazard Assessment (FHA) and subsequent PSSA/SSA work. It’s tailored for a 737/A320-class single-aisle with hybrid propulsion. I’ve written functions in “provide/perform/ensure/monitor/protect” language to make them FHA-friendly and grouped them by system. Use across all phases (preflight, taxi, takeoff, climb, cruise, descent, approach/landing, go-around, diversion, abnormal/emergency).

0) Aircraft-Level & Operational

Provide safe flight and landing in all operating conditions and required dispatch configurations.

Provide continued safe flight and landing following single failures and specified multiple failures.

Provide performance to meet certified field lengths, climb gradients, obstacle clearance, and missed approach.

Provide ETOPS/LROPS capability (if targeted) including dispatch, en-route diversion, and cold-soak.

Provide crew procedures, checklists, alerts, and training cues for normal/abnormal/emergency ops.

Provide aircraft configuration management across all phases (flaps/slats/gear/bleeds/energy modes).

Provide environmental qualification and lightning/HIRF/EMC robustness for all systems.

Provide crashworthiness, occupant protection, and emergency egress.

1) Propulsion & Hybrid Energy Management

Provide required thrust across envelope (including hot/high, degraded modes).

Provide hybrid power blending (thermal engine + electric motor assist) to commanded thrust.

Provide engine start, stabilization, and shutdown (air/ground, normal/abnormal).

Provide motor-only taxi (if applicable) and low-emissions ground ops.

Provide mode management: ICE-only, electric-assist, electric-only, charge-sustain, charge-deplete, idle-charge, regen (if implemented).

Provide automatic energy optimization vs. mission phase, noise, emissions, and thermal limits.

Provide autonomous reversion between modes upon failures or limit exceedances.

Provide propulsor/motor torque control, synchronization, and surge/stall protection.

Provide engine/motor relight/restart capability within defined envelope.

Provide FADEC/EMDEC (engine + motor controller) command/monitoring, built-in test, and fault accommodation.

Provide thrust asymmetry management, automatic thrust reduction/shutoff upon hazardous conditions.

Provide vibration/overspeed/over-temperature/over-current protection for engines, motors, gearboxes, inverters.

Provide fire/overheat detection and extinguishing for nacelles, e-machines, power electronics, and battery bays.

Provide safe shutdown and electrical isolation for uncontained failure or fire.

Provide inlet/propulsor ice protection and FOD protection (incl. motor & inverter).

Provide thrust/torque limits to protect structures/shafts/gearboxes.

2) High-Voltage (HV) Energy Storage & Power Electronics (Hybrid-Specific)

Provide HV battery energy storage sized for mission use cases (assist, taxi, APU replacement, emergency).

Provide battery management system (BMS): cell balancing, SOC/SOH/SOHx estimation, current/voltage/temp limits.

Provide HV contactor/interlock management and pre-charge/discharge control.

Provide battery thermal management (heating/cooling), cold-soak recovery, hot-day margins.

Provide venting, off-gas detection, smoke detection, and explosion relief paths; prevent propagation.

Provide crash/ditch protection, shock/vibration isolation, and liquid ingress protection.

Provide HV distribution buses, DC/DC and DC/AC conversion, and galvanic isolation.

Provide arc-flash, ground-fault, and insulation monitoring; automatic fault localization and isolation.

Provide emergency jettisoning or safe-containment strategy (as certified/allowed).

Provide HV maintenance lockout/tagout, safe approach indications, and interlocked access.

Provide EMI/EMC control for HV cabling, shielding, bonding, zoning, and common-mode control.

3) Conventional Electrical Power (LV & MV)

Provide AC/DC generation (IDG/Starter-Generators/Alternators) and conversion (TRU/rectifiers/inverters).

Provide primary/secondary electrical distribution, protection, and load management.

Provide automatic source selection, paralleling, and bus tie logic.

Provide load shedding and electrical emergency configuration for critical loads (fly-by-wire, comms, instruments).

Provide power quality (frequency/voltage/THD) and phase synchronization.

Provide APU/eAPU (if applicable) start, power, and bleed functions.

Provide external power interface and protection.

Provide lightning/HIRF protection, bonding/grounding, and static dissipation.

4) Fuel & Thermal Management (for ICE/Generator)

Provide safe fuel storage, quantity measurement, and management (transfer, balance, jettison if equipped).

Provide engine/auxiliary power unit fuel feed with air/thermal/vapor control.

Provide inerting/venting and leak detection/isolation.

Provide fuel system icing protection and contamination management.

Provide integrated thermal management (heat sinks for motors/inverters/batteries via fuel/ECS/ram-air).

5) Flight Controls (Primary & Secondary)

Provide pitch/roll/yaw control authority and stability augmentation.

Provide fly-by-wire command/monitoring, actuator control, redundancy, and reversionary modes.

Provide high-lift system control (flaps/slats) with asymmetry detection and protection.

Provide speedbrake/spoiler control with load alleviation and gust suppression (if implemented).

Provide trim systems (pitch/roll/yaw) with runaway detection and cutout.

Provide envelope protection (AoA, g-limit, overspeed) and stall protection/shaker/pusher as applicable.

Provide jam/icing/fault accommodation, and manual reversion strategy as designed.

6) Autoflight & FMS

Provide LNAV/VNAV, RNP/LPV/ILS approach guidance and autothrust integration (including hybrid modes).

Provide autopilot/flight director modes, mode integrity/annunciation, and reversion.

Provide autothrottle/autothrust with energy-aware thrust requests to FADEC/EMDEC.

Provide performance management (takeoff/landing data, speeds, derates, noise abatement).

Provide trajectory management, time-of-arrival control, and 4D operations (as required).

7) Navigation, Communication, Surveillance

Provide air data/inertial reference, GPS/GNSS, radio nav (VOR/LOC/ILS/GBAS/SBAS).

Provide radios (VHF/HF), data link (ACARS/ATN, CPDLC), SATCOM (if fitted).

Provide ATC transponder/ADS-B/ELT, TCAS/ACAS X (as applicable).

Provide weather radar, Lightning/Stormscope, and terrain awareness (TAWS/EGPWS).

Provide integrated time source and clock synchronization.

8) Display Systems & Flight Deck Human Factors

Provide PFD/ND/MFD/EICAS/ECAM-like alerting and synoptics, with hybrid energy pages.

Provide alerting/annunciation with prioritization and inhibition logic.

Provide control interfaces (thrust levers, mode selectors, flap/gear handles, HV enable/standby).

Provide takeoff/landing configuration warnings (including energy mode constraints).

Provide checklists (normal/abnormal), electronic flight bag integration, and performance tools.

Provide external visual references (lighting, HUD/EVS if fitted).

9) Air Data, Sensors & Health Monitoring

Provide pitot/static, AoA, TAT, OAT, vibration, and structural load sensing.

Provide integrated data concentration, time-stamping, and parameter validation/voting.

Provide condition-based maintenance (CBM), HUMS for engines/motors/gearboxes/batteries.

Provide fault reporting, maintenance messages, and safe-download/recording (FDR/CVR/Crash-Protected Memory).

10) Hydraulic/Pneumatic/Actuation

Provide hydraulic power generation, distribution, and backup (including e-pumps).

Provide leak detection, isolation, and quantity/pressure/temp control.

Provide pneumatic/bleed management (from engines/APU/eAPU/e-compressors) with over-temp/over-press protection.

11) Landing Gear, Wheels & Brakes

Provide gear extension/retraction, door control, and uplock/downlock indication.

Provide alternate gear extension method.

Provide steering control (incl. e-taxi integration if motors in wheels or propulsors used).

Provide braking (normal/alternate/parking), anti-skid, autobrake, and brake temperature monitoring.

Provide tire pressure/temp monitoring and fuse-plug protection.

Provide takeoff/landing performance monitoring (rejected takeoff logic/alerts).

12) Environmental Control & Pressurization

Provide conditioned air, ventilation, and humidity control for cockpit/cabin/equipment bays.

Provide cabin pressurization, schedule control, and outflow/safety valve protection.

Provide avionics/electronics bay cooling, battery bay thermal control, and smoke removal.

Provide ozone/air quality/particulate monitoring as required.

13) Ice & Rain Protection

Provide wing, tail, engine inlet, probe, and windshield ice protection (bleed, electric, or hybrid).

Provide ice detection (primary/backup) and logic to prevent exceedance of ice accretion limits.

Provide rain removal (wipers/hydrophobic coatings/heaters).

14) Fire Protection

Provide detection and extinguishing for engines, APU/eAPU, nacelles, battery/inverter bays, cargo, lavatories.

Provide cabin/cockpit smoke detection and ventilation/smoke removal.

Provide fire handle logic, fuel/HV isolation, and extinguishing agent control.

15) Structures, Doors & Flight Controls Surfaces

Provide structural integrity, fatigue/damage tolerance, and load paths for hybrid system additions.

Provide doors/hatches/rams/ram-air inlets with position sensing and locks.

Provide emergency exits operation and indication.

16) Cabin Systems & Passenger Safety

Provide seats/restraints, oxygen systems (crew/pax), and PSU control.

Provide interior/cargo lighting and emergency lighting with independent power.

Provide water/waste systems with contamination protection.

Provide galley power management and high-load interlocks (coordinated with aircraft electrical).

Provide IFE/Connectivity isolation from safety-critical networks (cybersecurity segregation).

17) Safety, Security & Cybersecurity

Provide system safety monitoring, fault containment regions, and fail-safe/ fail-operational behaviors.

Provide physical security of flight deck and critical bays.

Provide data/network security, partitioning, secure boot, updates, and key management.

Provide robust maintenance access controls and logging.

18) Ground Operations & Servicing

Provide turnaround support: refuel/defuel, HV charging or fast-charge, GPU/air cart connections.

Provide safe ground handling with HV interlocks and live-voltage indicators.

Provide brake cooling/time-to-dispatch and battery cooldown/charge-to-dispatch functions.

Provide de-icing/anti-icing interfaces and procedures.

19) Abnormal & Emergency Functions

Provide emergency electrical configuration (batteries/eAPU/ram-air turbine if fitted).

Provide emergency descent and pressurization protection.

Provide thrust-asymmetry compensation and degraded control law.

Provide smoke/fumes removal procedures and dedicated ECS modes.

Provide ditching/overwater equipment and sealing (if applicable).

Provide post-event safeing: HV discharge, engine/motor spindown, and fuel/HV isolation.

How to use this list in your FHA (Failure Hazard Analysis) quickly

For each function, define failure conditions (lost, erroneous, partial/degraded, unintended, latent).

Map each to operational phase(s) and environment (icing, lightning, ETOPS, MEL).

Assess effects (crew workload, injuries, aircraft damage) → classify (No Safety Effect, Minor, Major, Hazardous, Catastrophic).

Derive safety objectives (DALs, integrity levels, detection coverage, independence, segregation).

Feed into PSSA (architectural mitigations), then SSA (evidence, FTA/FMEA, tests).

If you want, I can drop this into a structured spreadsheet (columns for Function, Failure Condition, Phase, Effect, Classification, Mitigations) and pre-fill the hybrid-specific items so you can start marking hazards right away.

Our Comments

While ChatGPT’s response isn’t necessarily awful, it clearly shows that it doesn’t know how to distinguish what is needed at an aircraft-level and what needs to be defined at a system-level. It is also confused about the differences between functions, requirements, and solutions.

An aircraft function describes the behaviour of the aircraft, whereas a system function describes the behaviour of the system that is required to support an aircraft function. For example, an aircraft function could be to provide a habitable environment for crew and passengers. The system function would be that the Environmental Control System (ECS) provides thermal airflow control for crew and passengers.

As for the differences between a requirement and solution, one of the system requirements for the ECS could be that it should modulate the cabin temperature to +/- 2 degrees Celsius from a crew-adjustable setpoint, between 18 and 30 degrees Celsius, under normal operation. The solution could be a thermal management controller that can read sensors and control actuators, and has some built-in test capabilities.

We asked ChatGPT for aircraft functions, but the output, “[p]rovide FADEC/EMDEC (engine + motor controller) command/monitoring, built-in test, and fault accommodation”, is a mix of system-level requirements and solutions rather than an aircraft function. “Provide de-icing/anti-icing interfaces and procedures” sounds like a random mix of words.

From the experiment above, we can see that AI has the ability to quickly consolidate a lot of information. ChatGPT was able to generate some form of an aircraft function skeleton. Yet, it is relatively weak in navigating subtlety and nuance. If the system is properly trained and used, it has the potential to create coarse content while permitting its human user to focus on subtle details that require critical thinking and judgment. It could also raise topics an engineer might have overlooked.

Related